First of all, thank you for actively developing these useful meshing tools.

I encountered behaviour of the mesh size settings that I did not expect in MMG2D (5.6.0).

I created a simple test mesh with a triangular hole of which the edges may not be altered. For all tests I added ‘-hgrad -1 -hgradreq -1’ to the input command line options.

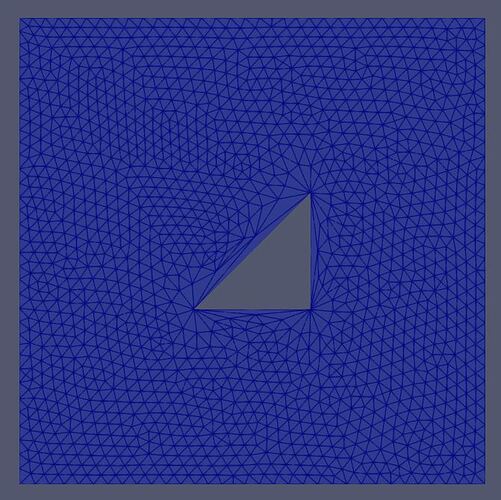

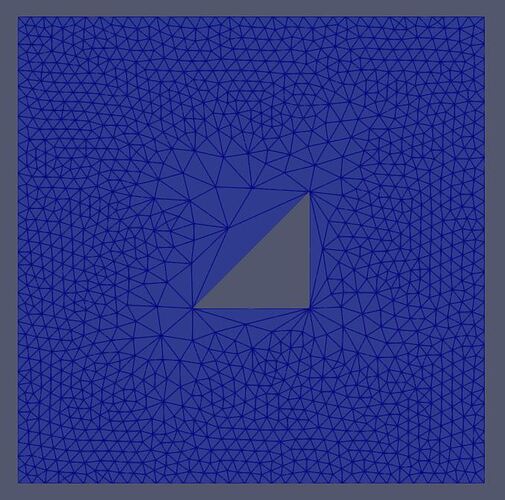

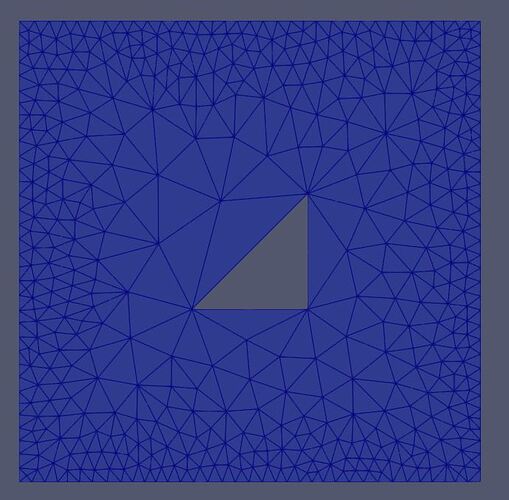

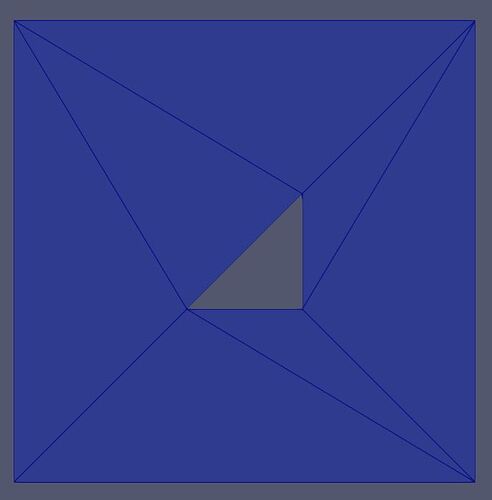

When I prescribe a maximum edge length of all triangles using the global options ‘-hmin 0 -hmax 0.1’ I obtain the expected results, see attachment 1. When I use an external parameter file “.mmg2d” to prescribe the same minimal and maximal edge lengths (and remove the global size options from the input string) for all triangles, I obtain different results, see attachment 2. The edge size seems to decrease much more gradually in this case. If ‘-nofem’ is added, the results are even worse.

Could you please help me figuring out what is going on and if this is unexpected behaviour?

Thank you in advance!